Continental’s work on high-performance computer functionality and virtual testing could accelerate the development cycle for SDVs. By Will Girling

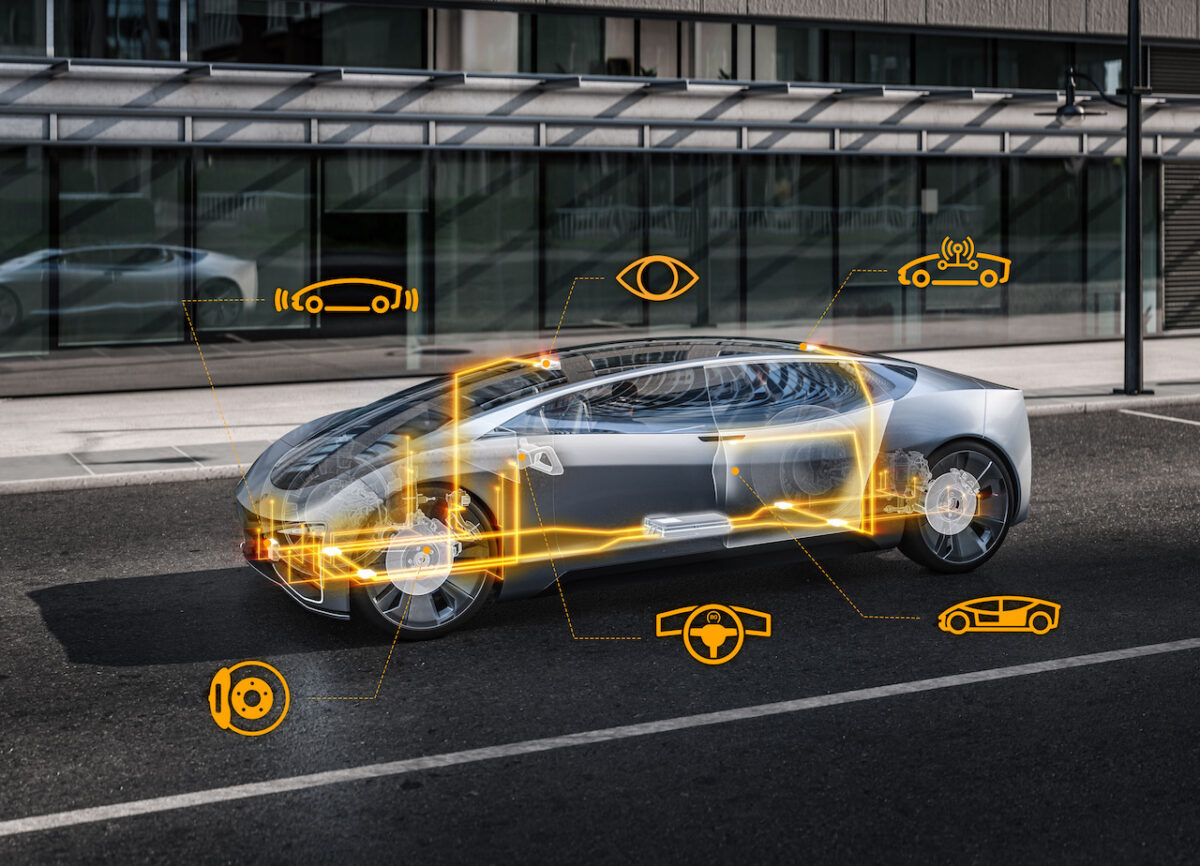

High-performance computers (HPCs) are a central component enabling the rise of software-defined vehicles (SDVs). This hardware provides the processing and computing power necessary for automakers to realise innovative, software-driven features. Combined with over-the-air updates, HPCs can enable automotive to iterate vehicle functionality continuously in an equivalent manner to the tech industry.

Today, automotive engineers continue to chase higher system performance while also seeking reductions in overall cost and power consumption. Enhanced HPC functionality could come increasingly under the spotlight as an important area for optimisation. As such, multi-national Tier 1 supplier Continental has been exploring not just how hardware and software can be enhanced to unlock new functions but also how to bring SDVs to the market faster.

Fragmentation to consolidation

Martin Schleicher, Head of Software Strategy at Continental, explains to Automotive World that the use of HPCs in vehicles has historically been fragmented. The first generations were kept separate from each other and targeted specific domains, such as cockpit and advanced driver assistance systems (ADAS). In May 2024, Continental became the first company to buck this trend by implementing a cross-domain HPC in a real vehicle.

The shift from domain to server-zone architectures enables vehicle electronics to be grouped into sections with their own ECUs and specific functions. For Continental, the critical enabling component was the Snapdragon Ride Flex System-on-Chip, which supports multi-modal workloads on a single hardware device.

“Cross-domain HPCs mean we can run ADAS functions on a cockpit computer, for example, even though their functionalities are usually separate,” says Schleicher. This includes complex features like automatic parking using ultrasonic sensors and surround view cameras. In addition to broadening system capabilities by consolidating several functions across the same HPC, Continental can deliver software updates and new functions.

Unlocking new business models

Although cross-domain HPCs hold exciting potential, Schleicher emphasises that their practical implementation is currently far from simple. Certain functions could require substantial graphics power or accompanying machine learning capabilities on the device to run properly. Discovering how disparate domains running on the same HPC interact will be an important learning experience. “That’s one of the reasons we’re doing this: to understand how far we can take domain consolidation,” he says.

Schleicher anticipates that consolidating systems will not only reduce vehicle weight and potentially shrink overall vehicle size over time but also unlock new business models. The ultimate outcome would effectively be general-purpose computers on wheels with sufficient compute power to add a wide variety of software-driven features over the lifetime of a vehicle—a distinct monetisation opportunity that only SDVs can unlock.

“By retaining the same hardware but upgrading the functionality with software, automakers can keep their cars attractive and differentiate their brand,” he says. “The flexibility of a cross-domain HPC will also allow them to move functions that don’t fit in one ECU to another, meaning OEMs can determine how and where their compute power is distributed.” Since everything in an electric SDV will be drawing from the same power source—the battery—customisable efficiency will also help maximise range, another important consumer consideration.

Building enthusiasm for SDVs

By 2030, McKinsey & Co forecasts that global automotive software and electronics will be worth US$462bn—up from around US$2.5bn in 2019. In the wake of the CrowdStrike system outage, automotive players will be more aware than ever that bugs and software errors can lead to disastrous results on a global scale. With the consultancy also estimating that 90% of vehicles sold by 2030 will have connectivity features, some of which will be critical safety functions, this is something the industry cannot afford to risk. The challenge with automotive becoming truly software-defined is that development must balance speed with safety: test cycles must be as short as possible to be competitive without creating undue risk because of unvalidated work.

Through the Continental Automotive Edge Framework (CAEdge), a cloud-based development environment, Schleicher states that automotive engineers could examine, develop, and maintain system software on a virtual HPC: “We can accelerate the time-to-market for new functions by allowing engineers to test new software in a virtual environment before it goes into production.” Continental estimates that CAEdge can generate five million virtual kilometres and 100PB of test data in just one week. By facilitating parallel hardware and software development, the company claims that product development cycles can be significantly condensed. “A cockpit HPC, for example, might have taken 24 to 36 months to validate. We can bring that down to 18 months,” states Schleicher.

Continental wants to demonstrate both what’s possible in terms of hardware and what we can offer automotive engineers as standalone software

The road to SDVs will be challenging: automakers must balance functionality, upgradability, and compatibility while also considering how a system fits holistically within the dimensions and specifications of a vehicle. Demand for these time and cost saving tools already exists, according to Schleicher, although the industry might need to wait up to three years for a fully commercially viable cross-domain HPC. “At this point, Continental wants to demonstrate both what’s possible in terms of hardware and what we can offer automotive engineers as standalone software functions.” He hopes this technical “showcase” will continue to build enthusiasm for the possibilities of SDV technology in the coming years.